ATS Allison Extreme Performance-Built Transmissions By Jim Bigley Photos by Jim Bigley & courtesy of the manufacturer The factory Allison 1000-Series 5/6-speed transmissions are simply the best and most durable automatic transmissions to ever have been installed in a GM pickup truck. When using stock power, it's practically impossible to hurt the transmission or exceed its torque handling capability. As good as the Allison is, however, it's still possible to exceed its ability when using more than stock power. Most Allisons will hang onto at least 75 additional horsepower and 200 lb-ft of torque, but living on the ragged edge can take a toll on long-term durability. This is why installing a performance-built Allison can increase the fun!   The above images dramatically illustrate one problem with a factory Allison when increasing power/torque. The image on the left shows a dyno run with a completely stock truck. The dips visible in the graph show how much power is reduced at each gear shift. The Duramax ECM & Allison TCM are programmed to pull fuel at each shift (reduce power), in part to protect the transmission and to produce the great drivability we enjoy. The ECM/TCM use various sensors inside the transmission that look for torque converter clutch or C1-C5 clutch pack slippage, and will reduce power at each upshift even further if any is detected. The image on the right shows what happens when adding another 140 horsepower. Yes, the fresh factory Allison was able to hang onto the power/torque (this time), but it struggled greatly with each upshift. Slippage during each shift forced the TCM/ECM to pull a lot more fuel than it normally would have in an attempt to prevent slippage. The net result is a long-long shift delay. If you're after quicker 1/4-mile times, full pulls at the sled track or want to use big power on the street, you've got to build more torque handling capability into the transmission.   Billet torque converters are all the rage for performance transmissions, and ATS follows that trend. Our ATS Allison was installed in mid-2005 when the "Triple-Lok" was the TC of choice among trans builders and performance enthusiasts. ATS now offers their new 5-Star, which adds yet more clutch discs and additional torque handling capability. Original equipment single-disc torque converters can experience failure of the welded-on TC bolt lugs, or distortion of the comparatively thin stamped-steel OEM converter housing when pushed past their design limits. Billet converter housings eliminate these problems, and the new 5-Star should be able to handle all of the power that the Duramax 6600 can be modified to produce.   To add torque-handling capability, C1-C5 clutch packs are also upgraded with more discs and steels than OEM. More discs and steels add surface area to each clutch pack and increase torque-handling accordingly. When combined with higher clutch-apply pressures, the ability to hang onto the torque is multiplied. The ATS modified valve body is equipped with a new solenoid control valve (where none existed) and wiring harness, which allow the Co-Pilot in-cab controller to help you manage dynamic clutch-apply pressures.   Our ATS Allison had already been modified internally to accept control by the Co-Pilot in-cab controller. The Co-Pilot kit components include a wiring harness that T's into the factory transmission harness at the rear of the transmission. The harness also requires connection to a good electrical ground, the instrument panel Tow/Haul signal, throttle position sensor, vehicle speed sensor, and boost pressure sensor. A ¾" hole was cut in the firewall to allow the grommet protected Co-Pilot harness into the cab. Once inside the cab, route the harness to a location that allows mounting the control module in a location that provides easy access and view by the seated driver. The instructions included with the Co-Pilot outlines how to set the various functions, depending on how the truck is being used. Perhaps the best feature of the Co-Pilot is that you can set it to produce Pro-Stock type shifts while at the track or shift smoothly while making a run for groceries. According to ATS, the stock Allison transmission only receives approximately 86-PSI clutch-apply pressure when in 5th gear. The Co-Pilot kit boosts fluid pressures to a maximum of approximately 230-PSI. Increasing clutch-apply pressure increases the Allison torque handling ability by over 200 ft-lbs of torque. When combining the Co-Pilot kit and the installation of the ATS pump kit and converter (part of the Triple-Packtm kit), max pressure is increased further to around 290-PSI, which produces a 170% hydraulic increase in torque capacity - something to think about when pushing the Duramax even farther. The beauty of the Co-Pilot is that fluid pressures are dynamically controlled in response to engine torque and load. Most other performance Allison transmissions are modified to produce high fluid pressures more or less all the time, which can affect the long-term durability of things like seals, delivery rings, drums, shafts, and other parts.   ATS dealer Kennedy Diesel also offers an interface kit that makes it really easy to make the connection to the boost sensor wire on the engine. This kit accessory allows installing a removable extension that eliminates wire splices in the original sensor connector. The arrow in the photo on the right points to the LB7 boost sensor.  The Co-Pilot installation requires soldering a wire onto the circuit board found on the rear surface of the instrument panel. Doing the job correctly requires some experience with electronic soldering and the use of a 25-35 watt soldering iron. If you don't have the experience, get a local electronics shop to do the work for you. This connection allows the Co-Pilot to know when Tow/Haul is engaged, which helps it to better manage torque converter lockup and to increase the torque handling capability of the transmission.  It's a tight fit, but the new ATS Allison Extreme and NVG-263 pushbutton controlled transfer case fit quite well in our project vehicle's 1/2-ton chassis. So far, we've put as much as 600 horsepower and more than 1100 lb-ft of torque (rear wheel) through the transmission without a problem. Track shifts are quick and positive, and shifting feels nearly stock while just motoring around town. The ATS deep pan increases capacity by more than a gallon. I recommend you have about 6-gallons of Dextron III or IV ATF (depending on model year) on hand for the first fill. Increased clutch-apply pressures used in performance transmissions usually increase fluid temperatures somewhat. The dynamic clutch-apply pressures made possible by the Co-Pilot reduces these pressures during light-duty type driving, but our ATS Allison Extreme produces ATF temperatures slightly above those produced by a stock transmission. It takes about 4-½ hours to R&R an Allison, and I'd expect another 4 hours to install the Co-Pilot kit components. A vehicle lift and HD transmission jack are essential. ATS offers several different build levels (and prices) and optional accessories for their performance Allison transmissions. If you need (or want) to upgrade your Allison, contact Kennedy Diesel or ATS for more information. They have a lot of experience with the various build levels, and know what will work for a given application. Then go out and have some fun! TDP Sources: ATS Diesel PerformanceCall: 1-800-949-6002 www.ATSDiesel.com

Kennedy Diesel

What's New: | Feature Articles: | Product Reviews: | Member's Area: Join Us: | Duramax Diesel Page: | Advertisers: | Classified Ads: | Books:

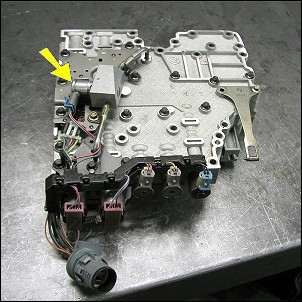

Send e-mail to: turbo@TheDieselPage.com |